Every retail company, large or small, should have some form of inventory management. Understanding your inventory is crucial to running a successful business. You need to know:

- When to reorder

- What to reorder

- How much you’ll need to order

- How long can you expect your stock to sit in the warehouse

- And much more

How much money do you have tied up in inventory right now? Money that is actively depreciating in value rather being used to increase company profits?

After reading this article, you’ll have several inventory management techniques to put into practice today, plus two new, cutting-edge methods that have only recently been perfected. Stop losing money: start managing your inventory more effectively.

What is Inventory Management?

At its simplest, inventory management describes how companies keep track of their product inventory:

- Ordering

- Storing

- Selling

In the new world of omnichannel communication, where customers can order through multiple touchpoints, many large companies rely on inventory management software to keep their systems up-to-date, but even for a small store, inventory control is an important thing to have.

Why is Inventory Management Important?

The inventory management process, in some form or another, has existed for centuries. That said, today’s market is more customer-centric than ever, and having a more thorough inventory strategy to manage inventory in your warehouse is becoming a necessity.

Without an inventory management plan, you won’t know when you are understocked, leading to orders you can’t fill. You won’t know when you’re overstocked, leading to unnecessary warehousing costs. And store inventories become increasingly complex the more you scale: this isn’t a problem that goes away.

You need to know how to manage stock and maintain inventory, even when something unexpected comes up. The type of inventory management may vary (and we recommend using more than one type of inventory management), but successful retailers always have some form of inventory control management.

The list of inventory management ideas covers five of the most popular inventory control strategies, followed by two new, AI-enhanced ways to manage inventory even better.

Top 5 Inventory Management Techniques for Online Retail

1. Inventory Management Technique: ABC Analysis

What is the ABC Analysis?

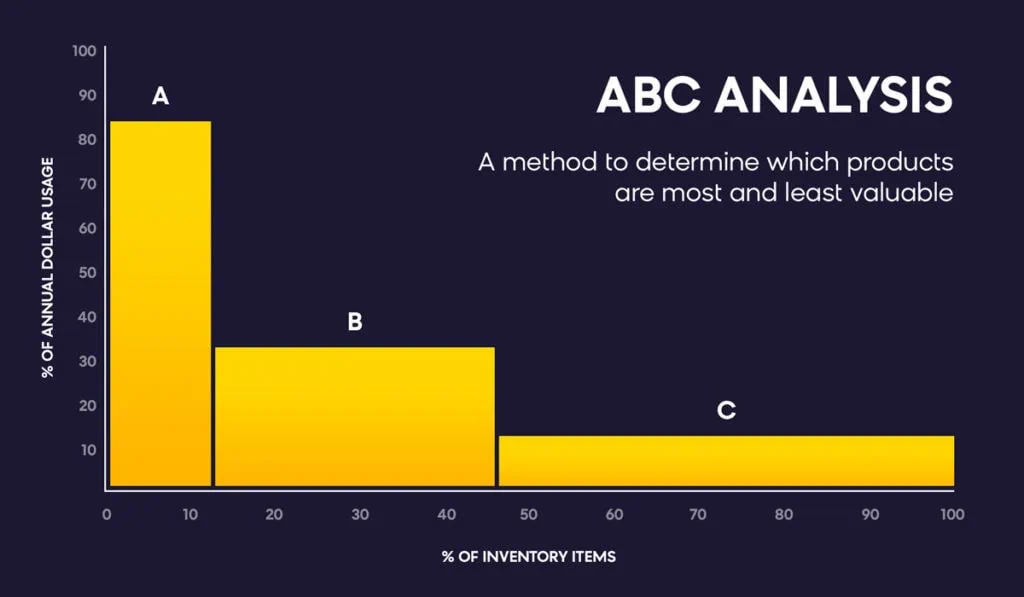

An ABC analysis is a way of determining which of your products are most and least valuable, so you have an idea of where to spend your time and effort. The analysis is based on the Pareto Principle (AKA the 80/20 rule), which boils down to this: 80% of the effects come from 20% of the causes.

We can use this analysis to find our most effective 20% of products, so we know where to focus.

Let’s try a step-by-step approach to work through this important, but potentially confusing, inventory management strategy:

- Make a list of all your products, how many you have of each, and the prices.

- Multiply each product by the amount in stock to find its potential revenue

- Put the products in order from highest potential revenue to lowest

- Add the potential revenue for each product together to find your total potential revenue

- For each product, divide that product’s potential revenue by the total potential revenue to find what percentage that product contributes to your revenue

An ABC Analysis then has you divide your entire inventory into three categories based on the product’s total value to the company. The three categories often end up looking like this:

Segment A: Products that provide 80% of total revenue, and 20% of stock

Segment B: Products that provide 15% of total revenue and 30% of stock

Segment C: Products that provide 5% of your total revenue 50% of stock

These segments will vary depending on the business, so here’s another way to think about them:

Segment A: High value products that don’t take up a lot of warehouse space

Segment B: Medium value products that take up an average amount of warehouse space

Segment C: Low value products that take up a lot of warehouse space

Why Should You Use an ABC Analysis?

Dividing your inventory into these three segments gives you a way to find and focus on the products that affect your business the most. It informs you of which items need constant restocking and which don’t, lowering your working capital costs by reducing the amount of obsolete inventory you have on-hand.

With the knowledge of which products bring you the most value, you’ll know which items are most important to ensure you have in stock. You’ll know which items are worth counting regularly, and which items to negotiate better margins on with your suppliers.

2. Inventory Management Technique: Setting Par Levels

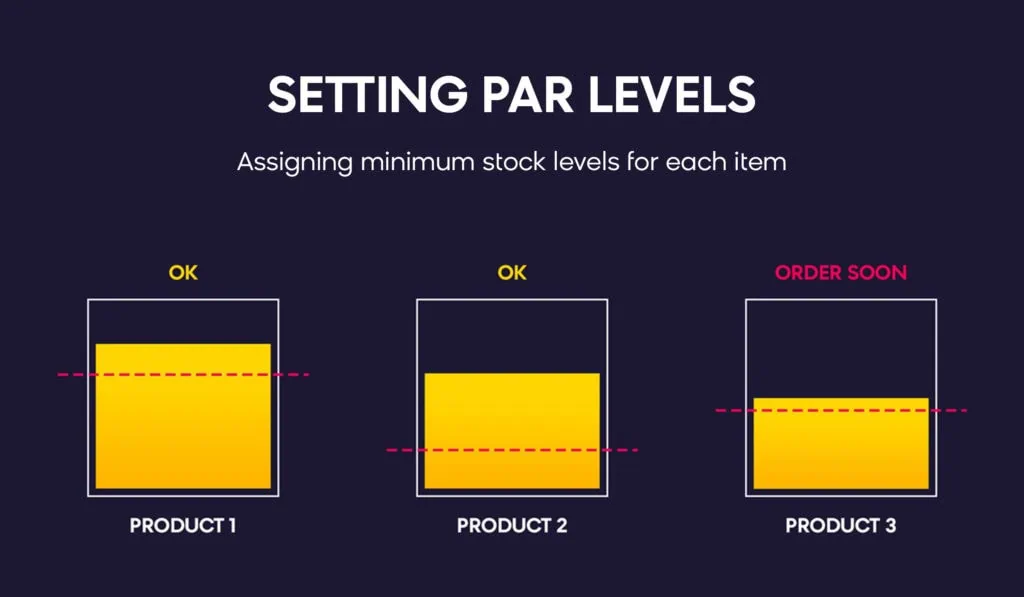

What Does Setting Par Levels Mean?

Setting par levels means assigning a minimum amount of stock for an item. If the stock goes below that level, you know that reordering that item is a priority. Your par levels should be consistently re-evaluated to ensure the amounts are aligned with your current demand. This article describes setting par levels for a restaurant, but is applicable to retail inventory management as well.

Why Should You Set Par Levels?

Par levels provide structure for your ordering process, assigning priority to items that need to be ordered immediately , thus separating them from items that do not. Par levels also allow for inventory orders to be placed by employees who know less about your inventory than you do.

3. Inventory Management Technique: First in First Out

What Does First In First Out Mean?

When using the first in first out (FIFO) technique , you focus on selling the oldest goods in your warehouse first (the ones that arrived first). This inventory management technique is a natural fit for many companies, as it tends to match the way the goods naturally flow. You’ll need a well-organized warehouse to make sure you’re moving the right goods, but this is a great inventory management system to start with.

Why Should You Practice First In First Out?

While inventory control methods like this are most important for companies producing perishable products, it’s also important for retail inventory management. If you’re in the fashion industry, you generally want to get the first clothes that reach your warehouse out onto the sales floor ASAP: something that’s in fashion right now may not be next month. Regardless of your industry, products that sit in warehouse for too long may start showing wear-and-tear. It’s less strain on your record-keeping system as well, as you won’t have to continuously account for much older stock.

4. Inventory Management Technique: Keeping Safety Stock Inventory

What Does Safety Stock Inventory Mean?

Safety stock is extra inventory that’s kept in case more stock is needed. It’s always a challenge to correctly predict what the product demand will be, and having safety stock protects you from running out of your best sellers. That said, you don’t want to carry too much extra stock, because it will add to the cost of storing your products.

Why Should You Have Safety Stock Inventory?

The best laid plans of mice and men often go awry. Even if you’re employing other techniques to keep your inventory in control, having safety stock will protect you from an unexpected turn of events. It’s also a key metric to know when you’re figuring out the best time to reorder.

See our article about the reorder point formula to learn the ideal time to order more stock.

5. Inventory Management Technique: Regular Inventory Auditing

What Does Regular Inventory Auditing Mean?

Whether you’re checking your store inventory control methods, or on the stock management of a warehouse, there are a few ways ecommerce companies tackle this massive task :

A FULL AUDIT

Like it sounds, this is a full-on counting of every item in the warehouse. It’s long, it’s exhausting, and it’s usually done no more than once or twice a year.

A PARTIAL AUDIT

This process is also known as cycle counting. Rather than going in and counting every item you have all at once, a partial audit splits the task up throughout the year, so something is always being checked against your recorded numbers. One advantage of using partial audits is that you can use the accuracy of one of your cycle counts to get an idea of the accuracy of your numbers for the rest of the warehouse.

SPOT CHECKING

Spot checking is another way to spread out the inventory count. With spot checking, you randomly choose a product at any time, and compare the actual count to the numbers in your software. This is a good way of periodically testing to make sure your numbers are accurate.

Why Should You Practice Regular Inventory Auditing?

Even with all the inventory management software and other inventory management tools at your disposal, it’s still good practice to include an old fashioned product count. You can find mistakes you didn’t expect, as well as account for products that may have been stolen during the period. If you never check the physical inventory, you run the risk of acting on inaccurate information, leading to overstocking and understocking issues.

2 (Better) Inventory Management Methods For Ecommerce

The five inventory management methods above are classic and useful. They are important to understand for inventory management. These next two have only recently been made possible due to new technological advances- Bloomreach has been leading this effort toward more effective inventory management tools

1. Inventory Optimization Technique

Analyze and act on your data in real-time to ensure accuracy.

What is inventory optimization?

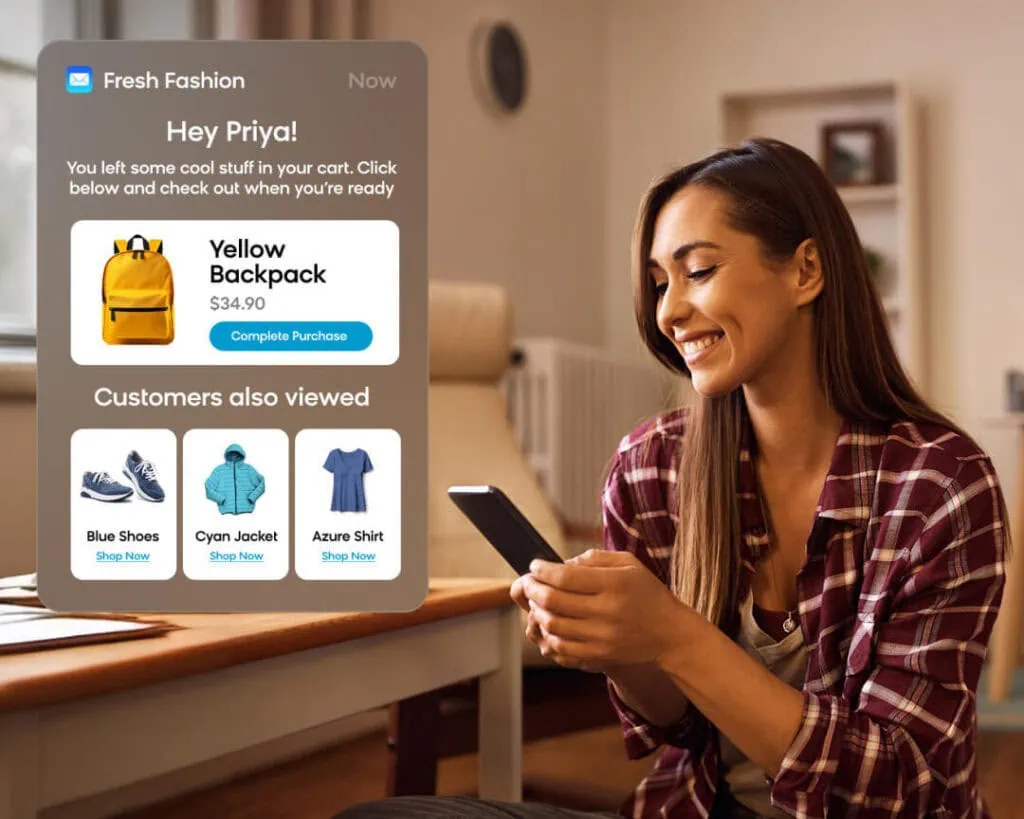

Bloomreach’s inventory optimizer analyzes your historical data, taking your safety stock level and your lead time (time it takes for a product to arrive in your warehouse after ordering) into account. The inventory optimizer then uses these insights to determine the ideal time to reorder each product, avoiding over or understocking issues. It even suggests what volume you’ll need.

If sales of your products are affected by seasonality, the inventory optimizer is a great help: it takes the season into account, and adjusts the reorder recommendations to match the time of year. If seasonality is irrelevant to the product, the inventory optimizer will adjust it’s suggestions to be based on where that product is in its product lifecycle.

Looking ahead, the inventory optimizer will soon be able to integrate the reorder insights with customer recommendations. This will create even more opportunities for ensuring optimal stock levels.

Why Should You Use Inventory Optimization?

You can find your reorder print without this sort of software, but it will take you a lot longer and it won’t be as accurate. Beyond that, the inventory optimization software updates itself as your inventory changes, accounting for changes in season or in consumption. Without the software, you should re-examine the reorder point of each product periodically to be sure nothing has changed.

2. Price Optimization Technique

What is Price Optimization?

“The price optimizer considers margin, purchases, and product views to find the ideal price for each product.”

-Vladimir Visnovsky

The price optimizer enhances your discount strategy. It provides you with recommendations for higher or lower discounts for each product, based on product performance. Like the inventory optimizer, the price optimizer takes seasonality and into account, adjusting the discounts accordingly. If seasonality is irrelevant, the price optimizer will use product lifecycle stage instead.

Why Should You Use Price Optimization?

The optimized discounts made possible by the price optimizer increase your profit. They prevent you from losing money on products that are priced too high, and they protect your margins by ensuring that popular items don’t sell for too little. From the perspective of managing your inventory, the price optimizer also helps you to clear products that weren’t selling at their previous price points, creating more space in your warehouse.

Final Thoughts

This article focused on inventory control techniques. If you’re interested in other aspects of inventory management, stay tuned: our next few articles will discuss other inventory management examples, and include more inventory management tips to make sure you’re not leaving money on the table.

It’s difficult to cover all the important techniques you need to know for inventory management. There are many different inventory management strategies, but they all boil down to this: keep track of what’s coming in and what’s going out, and know when you need to order more.

If you can do this without the need for software, that’s great. If you’re starting to grow and you need something that can help you manage your inventory while scaling, schedule a personalized demo to see what the Bloomreach Commerce Experience Cloud can do for your company.